We Offer DHL EXPRESS Flat Rate Shipping Worldwide. Just $10 USD for US, Canada, Australia, Asian countries. US$15 for Europe and other Countries in the world

We Offer DHL EXPRESS Flat Rate Shipping Worldwide. Just $10 USD for US, Canada, Australia, Asian countries. US$15 for Europe and other Countries in the world

Honyaki knives are most appealing to experienced users and professionals that demand the very best knives available. As we shall explain below, Honyaki knives are also the most challenging knives for forge smiths and craftsmen to produce.

The ‘one-piece’ blade construction of the Honayki knife is handcrafted using processes which are similar to those used in Japanese sword making, such as the Tsuchi-Oki process. This method involves heating the blade to around 800°C, quenching it in water to increase its hardness and then placing it in rice-straw ash to slowly cool down to room temperature; This detail is important since it helps to prevent uneven tension from developing in the blade

Sukenari have used their rich experience and knowledge to determine what methods work the best when making Honyaki knives and have also managed to develop a keen sense for what variables are important: The traditional hammer forging techniques used to shape the blade; the special ingredients for the Tsuchi-Oki (Clay mixture) and its application to the blade; carefully managing the temperature of the blade during the water-quenching process. Every step of production is perfectly demonstrated by Sukenari’s Master forge-smith and faithfully passed on to the next generation.

As you may know, Sukenari produced a Honyaki White Steel No.1 Series of knives up until a few years ago, but they unfortunately had to discontinue production because they used up all of their White Steel No.1 stock and had trouble securing more steel.

Fortunately, Sukenari recently decided to make a new series of Honyaki Knives with White Steel No.2. There is long, good story and history which explains how these Honyaki White Steel No.2 knives were originally created and by Sukenari:

About 5 years ago, when we started to do business with the historical and reputable Traditional Forged Knife Maker Sukenari, we had a meeting with Master Hanaki, the president of Sukenari). At that time, Master Nagao, our favourite knife maker and president of "Hiromoto", had decided to retire and close his company. Master Nagao decided to pass down his tooling and precious blade steel stocks to his partners, fellow craftsmen and knife makers, in order to aid the next generation and their future business. Master Nagao decided to pass his White Steel No.2 on to Master Hanaki, the president of Sukenari - I was excited to be with Master Nagao and Master Hanaki during this special moment, when a great Master Craftsman passed on his passion and best wishes for the next generation of talented, experienced knife makers and the future of the Japanese knife industry.

Now, nearly 5 years have passed. Master Hanaki and Sukenari are now producing true masterpiece White Steel No.2 Honyaki knives and we are very proud to introduce the Sukenari White steel No.2 Honyaki knives.

Each one of Sukenari’s Shirogami #2 Honyaki knives is beautifully mirror-polished and has an impressive wavy Hamon pattern. The blades are very thin just behind the cutting edge and have a rounded finger choil that is very comfortable. This Sukenari Honyaki Wa Gyuto Knife is fitted with a traditional octagonal Ebonywood handle that has a water buffalo horn ferrule and Red-Spacer. A matching Black Lacquered Wooden Saya is also supplied for safekeeping.

The Gyuto is the Japanese version of the classic Western Chef’s knife. It can be used with a variety of different cutting techniques to achieve a wide range of kitchen tasks and is suitable for cutting the vast majority of meats, fish, vegetables and fruits. The Gyuto is true multi-purpose knife. Compared to a Western-style handle, the lightweight traditional Japanese handle of the Wa Gyuto knife moves the balance point of the knife further towards the tip, which makes it feel more nimble and precise.

Please note that while Honyaki knives offer truly remarkable hardness, edge sharpness and edge retention, they are also difficult to sharpen and can be easily damaged by incorrect usage. In Japan, they are normally only used by very experienced top-star Chefs, so we similarly only recommend them for people who have extensive experience with traditional Japanese knives, or to knife collectors.

Knife Model: Sukenari Honyaki White Steel No.2 Series Wa Gyuto 240mm

Blade Material: White Steel No.2

Rockwell Hardness (HRc): 64

Blade Grind and Edge Shape: Double Bevel Edge 50/50

Handle Material: Octagon Shaped Ebonywood Handle with Water Buffalo Horn Ferrule & Red Spacer

Saya Included: Yes.

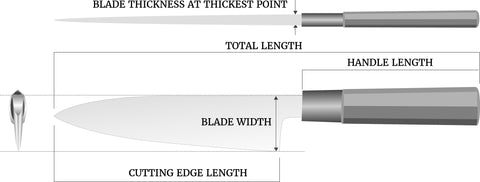

| Wa Gyuto 240mm (9.4") Cutting edge length: 232mm Total Length: 393mm Blade Thickness: 2.4mm Blade Width: 51mm Handle Length: 144mm Total Weight: 197g |

This knife comes with 50/50 double bevel edge geometry for both right and left handed use.

For your information, Japanese Kitchen knives are generally designed for right hand use with a slightly thicker and rounded grinding on the right side blade and a less rounded (almost straight flat) grinding on the left side blade. However, both right and left hander can use the knives that have double bevel edge sharpened 50/50 without problems.

We believe the quality and cutting performance of Japanese knives are the best in the world, and hope you enjoy fine craftsmanship and sharp edge with your new knife. With proper cares, every Japanese knife should be your special cooking partner for long times.

Important

This is the Carbon steel blade kitchen knife that can get rust and discolor easily, and requires extra care and attention to prevent rust.