We Offer DHL EXPRESS Flat Rate Shipping Worldwide. Just $10 USD for US, Canada, Australia, Asian countries. US$15 for Europe and other Countries in the world

For our U.S. Customers — No extra fees! All orders ship via FedEx DDP (duties & tariffs are covered by JCK). Enjoy fast, worry-free delivery! Learn More

We Offer DHL EXPRESS Flat Rate Shipping Worldwide. Just $10 USD for US, Canada, Australia, Asian countries. US$15 for Europe and other Countries in the world

For U.S. Customers:

SHIROU-KUNIMITSU is a genuine Japanese sword smithing family lead by Mr. Komiya, in Fukuoka Prefecture (Kyushu Island) — This real family of artisans are devoting their life and energies to preserving and utilizing the Japanese sword making and knife making traditions that have been maintained by their family since the year 1786. Currently, a total of 4 genuine sword smiths are passionately working together to create the finest Japanese swords and kitchen knives, which have outstanding cutting performance and practicality.

WABI-SABI (侘寂) is the best way to succinctly describe the characteristics of SHIRO-KUNIMITSU’s handmade, traditional hammer forged knives. WABI-SABI is a Japanese aesthetic / sensibility that suggests there is beauty within simplicity, imperfection and impermanence.

SHIROU KUNIMITSU rarely makes TAMAHAGANE (玉鋼, “Jewel Steel”) Kitchen Knives, typically only when they have received a special order request from the customer.

What is Tamahagane (玉鋼) ?

Tamahagane is a special type of steel that is traditionally used in the crafting of Japanese swords. It is highly regarded for its unique properties and it has a long, storied history of being the preferred material of Japanese blade smiths.

The term Tamahagane is often translated as "jewel steel" or "precious steel" due to the craftsmanship and expertise required to create it. It is characterized by a complex and labor-intensive smelting process, which involves heating iron sand (Satetsu) and charcoal in a traditional Tatara (A type of clay bloomery furnace). The resultant steel bloom contains iron and steel of varying carbon content, but, with great expertise and further labour, it can be further refined to create Tamahagane steel that has a distinctive grain pattern and superior cutting performance.

Tamahagane was historically prized for its high carbon content, which allowed the creation of blades with exceptional sharpness and edge retention. Tamahagane blades are not only highly prized for their functionality, but also for their cultural and historical significance as exquisite examples of Japanese craftsmanship and technological mastery.

Tamahagane is a unique and prized steel material that embodies the artistry and precision of Japanese blade making, and it a key component in the creation of high-quality swords.

Genuine Japanese Sword Smiths SHIROU-KUMITSU have mastered how to forge, quench and sharpen this special Tamahagane steel. To make their genuine Japanese Swords and blades, SHIROU-KUNIMITSU utilize the traditional Orikaeshi-tanren (折り返し鍛錬) technique; A labour-intensive process that involves repeatedly hammer forging and folding the special blade steel to increase its purity, uniformity and toughness.

The Orikaeshi-tanren process creates Tamahagane blades with many visible layers and a unique, beautiful appearance.

The forge-smith must take extra care when attempting to maximize the characteristics and potential of the Tamahagane because it is unforgiving to work with: For example, the suitable quenching temperature range for Tamahagane steel is very narrow. SHIROU-KUNIMITSU is truly one of the Masters of making Tamahagane steel knives.

One of our knife experts, who has used and owned Tamahagane knives, stated although Tamahagane steel knives has several demerits —Such as being very prone to discoloration and rust, and not reaching the same Rockwell hardness as popular Japanese carbon steels (e.g. White Steel No.2, Blue steel No.2 and Aogami Super)— he personally felt Tamahagane knives have their own unique appealing warmth and spirit, and their own ‘mysterious’ cutting power. Even though our knife expert is very experienced, he was still very excited to spend time with the Tamahagane steel knives and sharpen them.

This is because Tamahagane steel knives are uncommon not just outside Japan, but also within Japan.

We are very proud to introduce these rare Custom Order Made SHIROU-KUNIMITSU Tamahagagane Kitchen Knives and offer them to our customers. From time to time, we would like to continue producing “TAMAHAGANE Steel Kitchen Knives” with the SIROU-KUNIMITSU family of Japanese Sword Smiths.

This Custom Limited Edition SHIROU-KUNIMITSU TAMAHAGANE Wa-Gyuto 210mm knife was produced in collaboration with a Custom Handle Maker, who makes beautiful "one-of-a-kind" handles.

This Special Custom Order SHIROU-KUNIMITSU Wa-Gyuto 200mm knife comes with the Custom Handmade Octagonal Handle (Hybrid Wood Body with Forging-Fire-Red-Colored Resin infill and ferrule, collar and endcap, Nickel Silver spacers). For safekeeping, this knife comes with a matching magnolia wood Saya (Sheath) and a black pakkawood Saya pin.

The Gyuto is the Japanese version of the classic Western Chef’s knife. It can be used with a variety of different cutting techniques to achieve a wide range of kitchen tasks and is suitable for cutting the vast majority of meats, fish, vegetables and fruits. The Gyuto is a true multi-purpose knife.

A Note About Sharpening Shiro-Kunimitsu Knives: Please do not add a micro-bevel, as this can lead to micro-chipping of the already fine, sharp cutting edge. To maintain the flat factory bevel and bevel angle, we recommend placing the whole bevel flat on the whetstone and applying finger pressure between the cutting edge and Shinogi (The line formed by the bevel and main blade face / cheek) during each sharpening stroke. Please use the same number of sharpening strokes on each side of the knife and de-burr the wire-edge using very light finger pressure, alternating between bevels every few strokes until it is removed.

Knife Model: Shirou-Kunimitsu TAMAHAGANE “JEWEL STEEL” Series SKTJ-2 Wa Gyuto 200mm (7.9 Inch)

Blade Material: Tamahagane

Rockwell Hardness (HRc): 60 to ?

Blade Grind and Edge Shape: Double Bevel Edge 50/50

Handle Material: Custom Handmade Octagonal Handle (Hybrid Wood Body with Forging-Fire-Red-Colored Resin infill and ferrule, collar and endcap, Nickel Silver spacers)

Saya Included: Yes.

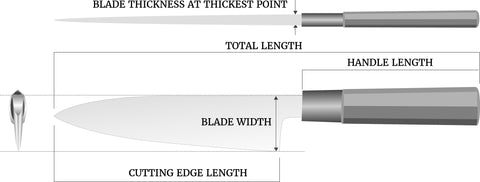

| Wa Gyuto 200mm (7.9") Cutting edge length: 192mm Total Length: 341mm Blade Thickness: 4mm Blade Width: 43mm Handle Length: 142mm Total Weight: 187g |

This knife comes with 50/50 double bevel edge geometry for both right and left handed use.

For your information, Japanese Kitchen knives are generally designed for right hand use with a slightly thicker and rounded grinding on the right side blade and a less rounded (almost straight flat) grinding on the left side blade. However, both right and left hander can use the knives that have double bevel edge sharpened 50/50 without problems.

We believe the quality and cutting performance of Japanese knives are the best in the world, and hope you enjoy the fine craftsmanship and its sharp edge of your new knife. With proper cares, every Japanese knife should be your special cooking partner for a long times.

Important

This is the Carbon steel blade kitchen knife that can get rust and discolor easily, and requires extra cares and attentions to prevent rust.